Client: A Fortune 500 global manufacturer of transportation fuels, other petrochemical products, renewables, and power. This publicly traded company employs over 10,000 people and was founded over 40 years ago.

Overview: Bill Spitzer & Associates (BSA) was selected for epoxy grout at the facility for all rotating and reciprocating machinery for a capital project expansion. As subject matter experts, BSA was needed to manage the epoxy grouting procedure because of technical aptitude and experience for cold weather circumstances. Additionally, almost 1” of precipitation occurred the day before grouting that created some site specific considerations. Generally, epoxy grouting temperatures should range between 55°F to 95°F without the concerns for proper polymerization and exothermic reaction of the epoxy technology to thermoset.

Location: Southern Louisiana

Date: January 2021

Grout: Escoweld 7505E/7530

Size: 184 units or 405ft3

Equipment: API Centrifugal

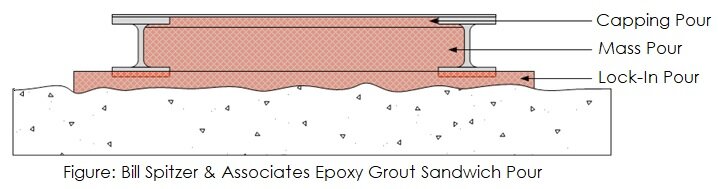

Avg Lock in Pour Depth: 2.5”

Avg Fill Pour Depth: 8”

Avg Cap Pour Depth: 4”

Avg Concrete Temp: 74°F

Avg Low Tent Ambient: 76°F

Avg High Tent Ambient: 87°F

Avg Low Ambient: 47°F

Avg High Ambient: 61°F

Max Wind Gusts: 18 mph

Avg Dew Point: 44°F

Avg Resin Temp: 59°F

Avg Aggregate Temp: 52°F

Avg Mixed Epoxy Grout Temp: 60°F

Cold Weather Key Decision-Making & On-Site Guidance:

Overall Constructability

Flowability to Temperature Reactivity

Epoxy Grout Viscosity to Flow Effectiveness

Proper heating of equipment, grout, and environments

Verification of concrete preparation, formwork rigidity & leak prevention, anchor bolt protection, clean & dry contact surfaces, proper jack bolts, expansion joints, grout conditioning, and adequate manpower

3-Day On-Site Technical Guidance:

Crew had been previously trained at the site for cohesive grout team capabilities

Discovered a leak in hooch that allowed water into the grouting area

Used heat, fans, & rags to evaporate & soak up water and moisture

Found missing bond prevention measures on the 3 pumps leveling screws

Reapplied antiseize

Secured constructability

Advised and instructed how to prep, mix, pour, and protect epoxy grout in cold weather

Analyzed and monitored project parameters, temperatures, wetness, and obstacles

Constantly calculated units needed to finish pours to be pulled from heated hooch

Supervised grouting process and sequencing

Implemented appropriate post-condition procedures for epoxy gout

Prevented overrun costs of a 4th day of grouting by beneficial project management

Escoweld® 7505/7530 Epoxy Grout:

3-Component, 100% Solids, & Versatile Epoxy Grout

Meets or exceeds American Concrete Institute (ACI) 351, American Petroleum Institute (API) 686, & Process Industry Practices (PIP) STS03601 specifications

Excellent bondability to itself without surface preparation

Similar Coefficient of Linear Thermal Expansion as Steel and Concrete

Steel: 14.6 x 6.1-6 / °F at 32°F to 140°F

Concrete: 5.9 x 10-6 /°F at 32°F to 140°F

Escoweld®: 14.6 x 10-6 / °F at 32°F to 140°F

PIP STS03601 Maximum: 30 x 10-6 / °F at 32°F to 140°F

ASTM C827/C827M, with accordance to ASTM C531

2.4 ft3 (68 L) Unit Coverage or Yield

2 Hour Pot Life at 77°F (25°C)

Epoxy Grout & at or Below 50°F (10°C):

The rate of build of glass transition temperatures (Tg) will be significantly slowed

One study showed that based on Arrhenius Law, a thermosetting bisphenol epoxy system has shown a 30% reduction in elastic modulus and strength

Might be from a decrease in plasticization

Recovery could occur if dryness, time, and temperatures are appropriate for the specific circumstance

(Development of physical and mechanical properties of cold-curing structural adhesive in a wet bridge environment: Savvilotidou, Vassilopoulos, Frigione, & Keller, 2017)

Solution:

Bill Spitzer & Associates (BSA) created a customized process for efficiently pouring Escoweld® 7505/7530 over three days. The uniquely technical aspects of cold weather epoxy grouting can be solved with BSA differentiated proficiency and aptitude. Furthermore, BSA advances engineers, owners, and contractors to become more profitable, timely, and productive. BSA operates a client first mentality or specialization. BSA also provided initial on-site contractor training and continues to administer instruction for the remaining schedule of the project and new labor. BSA is with the client every step of the way to prevent minor mistakes creating major issues.