HAZARDOUS LOCATION: SAFETY MEETS INNOVATION

At Bill Spitzer & Associates, we specialize in designing and manufacturing custom control panels specifically engineered for hazardous locations. Understanding the complexities and risks associated with these environments, we prioritize safety, compliance, and functionality in every panel we design and produce. Here are key considerations and capabilities we involve in producing custom control panels for hazardous locations:

1. Compliance with Industry Standards:

Our control panels are built to meet or exceed stringent industry safety standards to ensure the protection of both personnel and equipment in environments where explosive gases, dust, or flammable materials are present. We understand that failing to meet these standards can lead to catastrophic consequences. Some the common classifications we cater to include:

2. Advanced Safety Features:

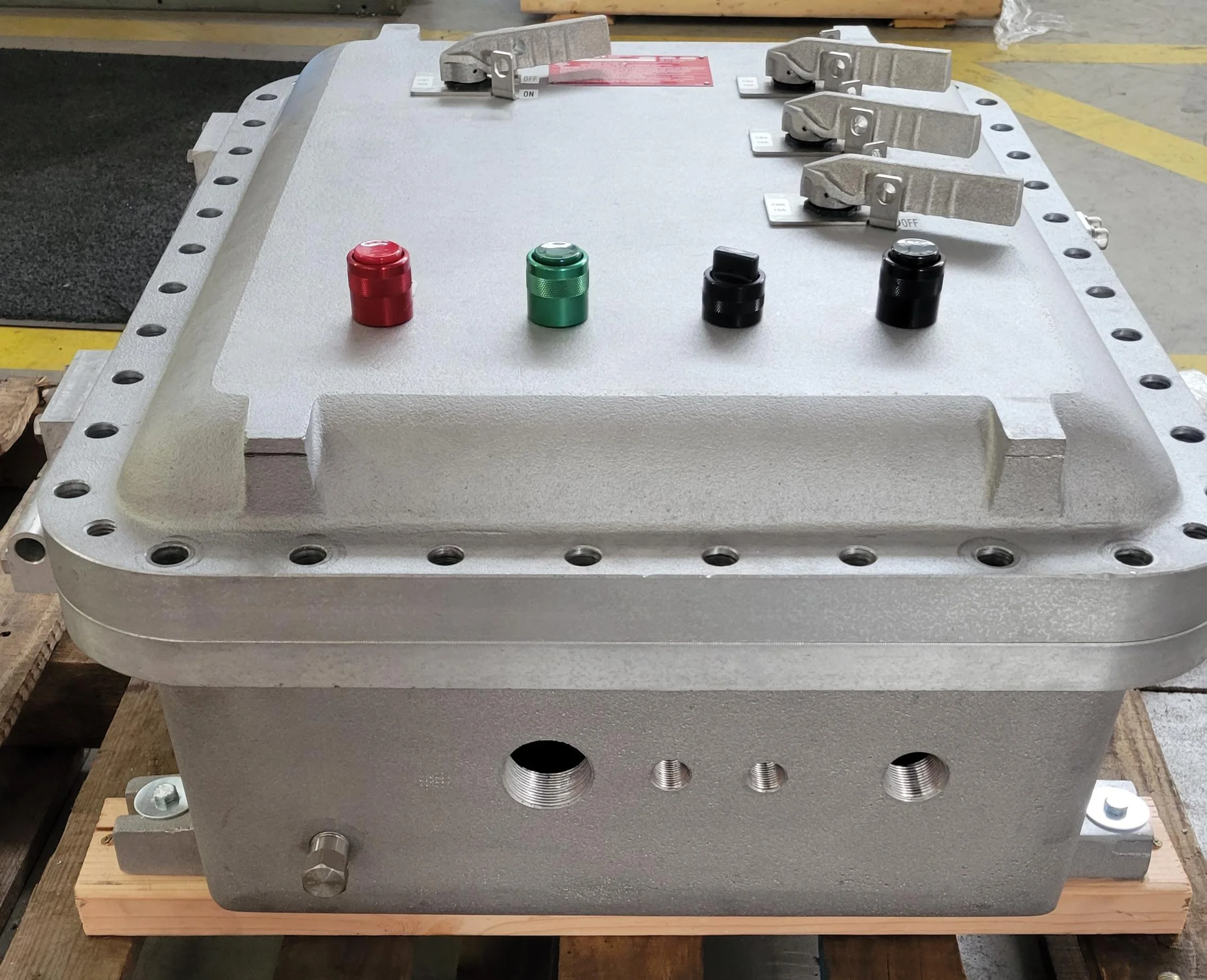

Safety is our top priority! We incorporate features such as explosion-proof enclosures, cable, fittings and fail-safe components to mitigate risks. Each panel is engineered to provide reliable operation in the most challenging conditions, ensuring both personnel and equipment are protected.

3. Robust Construction:

Our control panels are built to withstand harsh environments, including extreme temperatures, humidity, and corrosive substances. Using high-quality materials and rugged designs, we ensure long-lasting performance and minimal maintenance needs, even in demanding settings.

4. Documentation and Traceability

To meet stringent safety standards, manufacturers must provide detailed documentation and traceability for each custom control panel. This includes:

Engineering drawings and component lists, showing how the panel is constructed and the specific materials used.

Test reports, including FAT and other certification tests, to demonstrate compliance with relevant safety standards.

Quality Control (QC) reports, to play a crucial role in the manufacturing of custom control panels, to document the inspection, testing, and verification processes, ensuring that each panel meets all required safety, functional, and regulatory standards before deployment.

Industries We Serve

Our custom control panels for hazardous locations are ideal for a variety of industries, including:

Oil and Gas: Ensure safe operations in drilling, fracking, refining, and storage facilities.

Petro Chemical Processing: Manage risks associated with flammable materials and chemical reactions.

Mining: Control systems in underground and surface operations where combustible dust is a concern.

Your Partner in Safety and Innovation

At BSA, we understand that manufacturing control panels for hazardous locations is not just about technology; it's about safeguarding lives and assets. Our commitment to quality, safety, and innovation means you can trust us to deliver solutions that enhance your operations while ensuring compliance with the highest safety standards.

Class I, Division 1 & 2 (Gas and Vapors): Areas with the presence of flammable gases or vapors.

Class II, Division 1 & 2 (Dust): Areas where combustible dust may be present.

Class III (Fibers): Areas with ignitable fibers or flying’s.

All our control panels are designed according to the following regulatory classification standards:

NEC (National Electrical Code) Article 500-506: Defines the classification of hazardous areas in North America.

ATEX (EU Directive): Regulates equipment used in potentially explosive environments in Europe.

IECEx (International Electrotechnical Commission System for Certification): A global certification for explosion-protected equipment.